Introduction:

The iAuto automatic writing machine offers efficient and precise writing capabilities, but avoiding paper jams is crucial for optimal performance. Here, we delve into the top 11 tips to ensure a seamless writing experience with the iAuto, enhancing productivity and minimizing disruptions.

Want to advoid paper jam? Get the automatic paper dropping accessory kit here directly>>>

Top 11 Tips to Avoid Paper Jams with iAuto Automatic Writing Machine:

1. Manage Weight and Thickness:

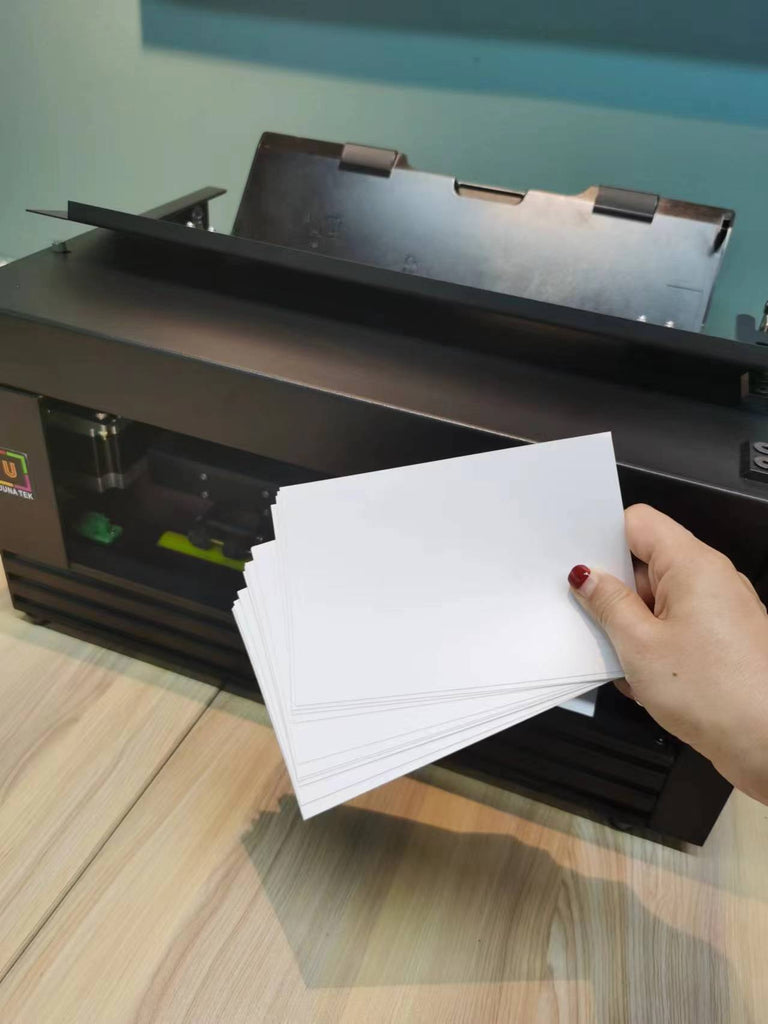

Maintain the weight of cards/envelopes between 70g/m² to 250g/m² and ensure a thickness of no more than 1cm. Calculate the capacity of your writing materials accordingly to prevent overloading the machine.

The iAuto automatic writing machine boasts an impressive capacity, capable of handling up to 80 A4 papers in a single operation. However, when it comes to cards and envelopes, the capacity differs significantly. Understanding how to gauge the machine's capacity for your specific writing materials is essential for smooth operation.

Typically, A4 paper weighs around 70g/m² per sheet. Therefore, the maximum weight capacity for the machine is calculated by multiplying 70g/m² by 80 sheets, resulting in 5600g. Additionally, the total thickness should not exceed 1cm.

For instance, let's consider a card weighing 210g/m². To determine the maximum number of cards that can be processed at once, divide the total weight capacity (5600g/m²) by the weight of each card (210g/m²). This yields approximately 26 units as the maximum quantity.

However, it's crucial to also consider the cumulative thickness of the cards. If the total thickness of 26 units exceeds 1cm, it may lead to operational issues such as paper jams. In such cases, reducing the number of cards is necessary to maintain optimal performance.

Moreover, it's important to note that many envelope sellers only display the weight of a single flyer, often neglecting to mention that envelopes consist of double flyers. This means the actual weight of the envelope is doubled. To avoid miscalculations, it's advisable to confirm the weight of envelopes with the seller before making a purchase.

By adhering to these guidelines and accurately assessing the weight and thickness of your writing materials, you can optimize the performance of the iAuto automatic writing machine, ensuring efficient and hassle-free operation.

Special guide for envelopes:

2. Opt for Smooth Surfaces:

Avoid using materials with matte or pearlescent finishes, as they can increase friction and contribute to paper jams. Opt for smooth, plain white writing papers for optimal performance. iAuto can't recognize the Black Paper/Cards/Invitation/Letters/Envelops, don't use Black writing material.

3. Prevent Cutting Edge Residue:

Prior to writing, shake the cards/papers/envelopes to dislodge any residual paper cutting edges, minimizing the risk of jams caused by stuck pieces.

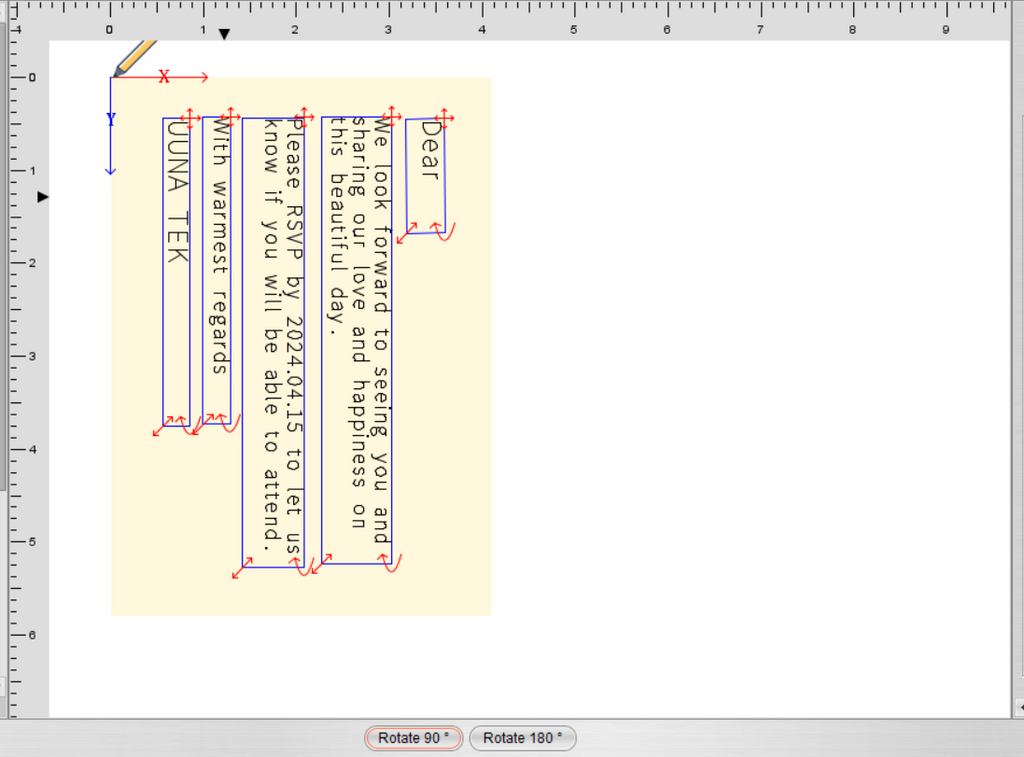

4. Vertical Placement:

For smaller cards/envelopes, place them vertically if they fail to drop properly after printing. Rotating them by 90 degrees can improve gravity and prevent floating. Check the guide here: https://www.youtube.com/watch?v=5kZp5u4uf10

5. Pad the Machine Bottom:

Enhance stability and gravity by padding the bottom of the machine, particularly useful for smaller cards that require additional weight for smooth dropping.

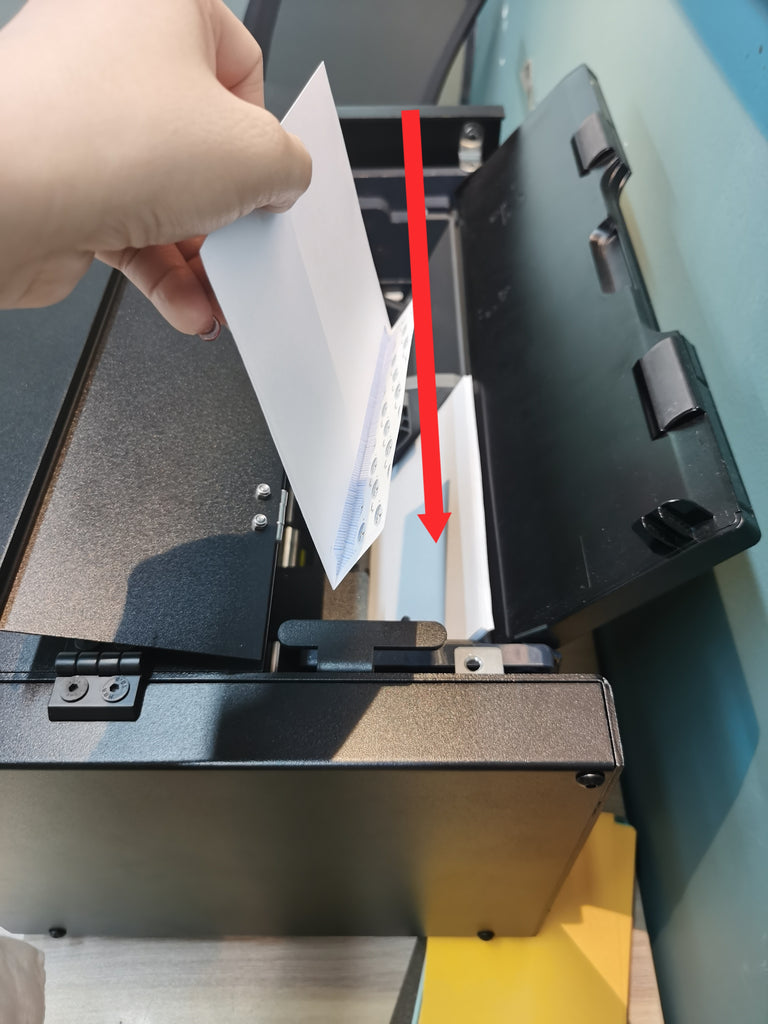

6. Strategic Envelope Placement:

Position envelopes with the flap at the back and downside in the tray to prevent instability and potential dragging of adjacent materials.

7. Test with Multiple Materials:

Test the machine with at least two different sizes and types of writing materials to ensure compatibility and identify any potential issues before full-scale operation.

8. Gradual Material Reduction:

If jams persist, gradually reduce the number of writing materials by 5 units at a time to pinpoint the optimal load capacity and alleviate jamming.90% of congestion is caused by an excess of writing materials, surpassing the capacity for writing. The easiest solution to this problem is to decrease the use of cards and envelopes.

9. Remove Pen Point Tape:

Eliminate the brown tape below the writing pen point, especially when writing on cards/envelopes, as it can contribute to jamming risks.

10. Check and Secure Screws:

Regularly inspect and tighten screws, especially after long-distance delivery, to maintain machine integrity and prevent structural issues that may lead to jams.

11. Keep Sensors Dust-Free to Prevent Paper Jams

Dust accumulation on the sensors of your iAuto automatic writing machine may cause paper jams or misalignment issues. To ensure smooth operation, regularly clean the sensors using a suction fan or vacuum cleaner. Keeping the sensors dust-free will enhance performance and extend the lifespan of your machine.

Summary:

Ensuring smooth operation and minimizing paper jams with the iAuto automatic writing machine is achievable through strategic material management, surface selection, and machine maintenance. By implementing these top 11 tips, users can optimize performance and maximize efficiency in their writing endeavors.

More related articles about iAuto:

- How to Automate Bulk A6 Card Writing with UUNA TEK iAuto Automatic Writing Machine

- How to Automate Bulk #10 Envelope Writing with UUNA TEK iAuto Automatic Writing Machine

- Get Thousands of Font Variaties with Font/Stroke Deformation Function

- Bulk Writing with iAuto Pen Plotter: Opening and Utilizing TXT or Word Files with Selected Fonts

- [iAuto Tutorial]Converting Text to SVG with Inkscape for iAuto Pen Plotter

- [iAuto Tutorial]Auto Wedding Invitation Production: A Guide with iAuto for Valentine's Day

- [iAuto Tutorials]How to Bulk Write Envelopes with iAuto Automatic Handwriting Machine

- [iAuto Tutorials]How to Install the software for UUNA TEK® iAuto Pen Plotter

- [iAuto Tutorials]How to Achieve Automatic Bulk Writing Using Various Fonts with iAuto Pen Plotter

- [iAuto Tutorials] How to Register and Connect to UUNA TEK® iAuto Pen Plotter

- [iAuto Tutorials]How to Make Bulk Greeting Cards with iAuto Auto Feeding Pen Plotter